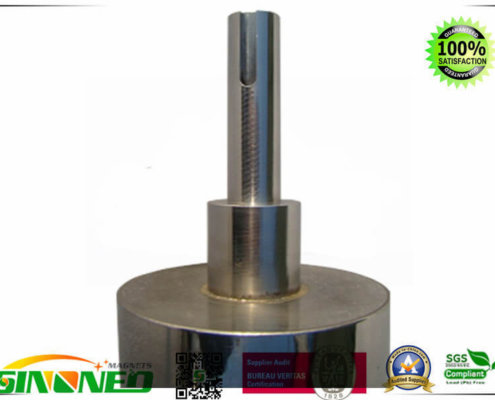

Strong, Full Welding, Easy Installed And Cleaning Magnetic Roller Sepatarors

Magnetic Roller Filters, Neodymium Magnetic Roller, Magnetic Head Pulley Separators

| Material: | SUS304/316/316L+NdFeB Magnets/SmCo Magnets |

| Shape: | Round Shape. |

| Diameter: | D50 D60 D75 D80 D85 D100 ……Up to 160mm |

| Length: | 300mm-2000mm, or customized as your request |

| Working Temp. | 80ºC~350ºC |

| Surface finish: | Polished |

| Magnet Strength: | 8000-19500Gs |

| Package: | Standard Export Cartons |

| Shipping: | By sea, By air or By express delivery (DHL/UPS/FEDEX) |

| Features: | Strong performance, full welding, easy installed and cleaning |

Sinoneo Magnet is a professional manufacturer and exporter of Magnetic Roller, Magnetic Head Pulleys, Magnetic head rollers Separator in china. We supply high quality of full welding, easy installed, and cleaning permanent rare earth magnetic roller within the time stipulated.

Permanent Magnetic rollers also called conveyor magnetic head roller or pulley, the magnetic roller has a very strong magnetic force and high Gauss surface value, and usually placed at the head of the conveyor belt, the materials with iron contaminations goes along with conveyor belt.

When they come into the front of the conveyor belt, as the limited region of the magnetic force of magnetic roller, the iron contaminations will go with the belt to the back of the roller, the good materials will fall down to the front of the roller as of gravity.

Sinoneo permanent magnetic roller is with unique magnetic circuit design, and consists of 304 or 316 stainless steel, high energy permanent rare earth magnets inside, such as neodymium magnets) or SmCo(Samarium-Cobalt) magnets.

The magnetic roller separators are used to separate ferromagnetic contaminants, iron particles and micromagnetic substance from the production streams in the belt conveyor systems by strong magnetic force, such as clods, pumice, stone, brick chippings and so on, so that to clean up the weak magnetic substance in the material effectively.

The magnetic roller usually is installed at the head of the conveyor belt.

Application Industry:

Mining industry

Grain industry

Plastic industry

Wood industry

Glass industry

Recycling industry

Coal industry

Refractory industry

Features of magnetic roller:

With joint spindle head to connect with the motor

Use the magnetic roller in conjunction with a belt to filter the magnetic impurities automatically

Easy installed and cleaning

Full welding design to a better protection

Environmental friendly and energy saving

Continuous working and no need to stop production when cleaning

Improve production safety and working efficiency

Low maintenance and save labor cost

THE ALTERNATIVE STANDARD SPECIFICATIONS OF MAGNETIC HEAD ROLLERS:

|

Part No. |

Diameter |

Length |

Gauss level |

|

SMHP-50 |

50 |

300-1500 |

8,000-12000gauss |

|

SMHP-75 |

75 |

300-1500 |

8,000-12000 gauss |

|

SMHP-80 |

80 |

300-1500 |

8,500-13,000 gauss |

|

SMHP-85 |

85 |

300-1500 |

8,500-13,500 gauss |

|

SMHP-100 |

100 |

300-1500 |

12,000-18,000 gauss |

|

SMHP-120 |

120 |

300-1500 |

12,000-18,500 gauss |

|

SMHP-150 |

150 |

300-1500 |

13,000-19,000 gauss |

|

SMHP-160 |

160 |

300-1500 |

13,000-19,500 gauss |

All dimensions in mm. Other dimensions can be provided on request.