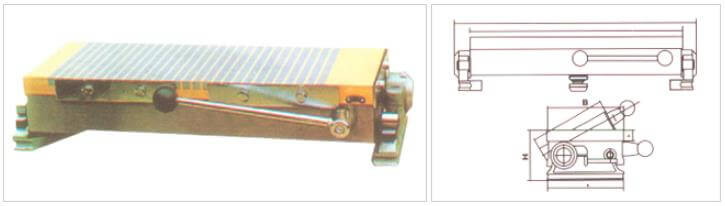

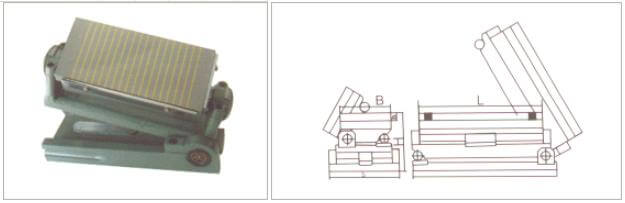

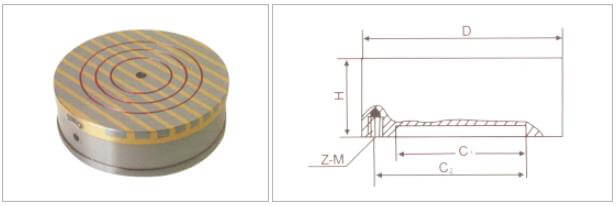

PERMANENT MAGNETIC CHUCK

Including the Rectangular magnetic chuck, Round magnetic chuck, Sine plate magnetic chuck, Wire-cutting versatile magnetic chuck, Rotatable, magnetic chuck etc.

1. It applies for surface grinder, sparkle machine and linear cutting machine.

2. When turning magnetic force ON/OFF, the flat face accuracy of magnetic force surface does not change and can keep high precision processing surface.

3. The fine-pitch magnetic poles make it ideally suitable for small and thin work pieces.

4. Made from permanent magnet, with strong magnetic force and little remained magnetism.

5. Specially designed for steady and high precision operation.

6. High performance magnetic steel in disc has strong suction and almost diminishes remnant magnet