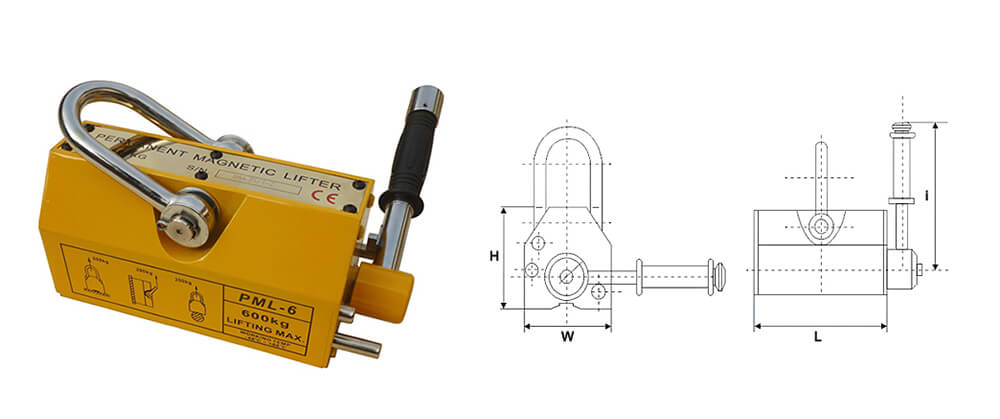

PERMANENT MAGNETIC LIFTER, NDFEB MAGNETIC LIFTER

Permanent Magnetic Lifters Model PML is mainly used for connecting components. During lifting and handling operation. They can hoist moving iron block, cylindrical. And other magnetic material. They are easy for operation, safety in handling, lightly, And ingeniously structured. Hence they are widely used as hoisting devices in factories, Docks warehouses, and transportation industries. By using them, you can improve Your working conditions and increase your working efficiency.

MODEL PML Permanent Magnetic Lifter has a strong magnetic path produced by NdFeB magnetic materials. On and off the magnetic path is controlled by turning the manual nozzle. There are shackles on the top of Magnetic Lifting Hoist for lifting, a veto slot on the holding face for holding cylindrical Components firmly.

The main uses and characteristics of Permanent magnetic lifter:

1. Widely used in the machining and mold processing industry.

2. Using high-performance permanent magnetic materials, with strong magnetic force, unique circuit design, remanence almost zero.

3. High safety factor, the maximal magnetic force is 3.5 times of rated lifting capacity.

4. Handle switches with safety button, easy for Single-hand operation, more safety, and convenience.

5. “ V” style design at the bottom of the lifter, can lift round steel and steel plate.

6. Without electricity, magnetic force permanent, more safety in use, and can be operated in the field.